Once a year owners of MGFs and TFs take a deep breath and cross their fingers – it is MOT time.

While generally regarded as reliable production vehicles, these cars have certain weaknesses that can be exposed when they go before an MOT inspector, so it is often well worth checking certain areas before the test.

One of the prime areas of failure is the electrics and more especially the lights. It is advisable to check beforehand that they are all working correctly. Sometimes the problem can simply be a blown bulb, while at other times it can be loose connections.

The rear lights in the boot are particularly vulnerable as the wiring is exposed and can be snagged when loading or unloading the boot. There are aftermarket covers available from the MGOC.

Tougher regulations on headlight function and, more especially, their brightness have been introduced in the last 18 months. Older models can suffer from two problems, fogging on the glass as they age and the deterioration of the silver reflecting surfaces – the latter can be resolved by fitting replacement refurbished units, which are available from club member John Heath.

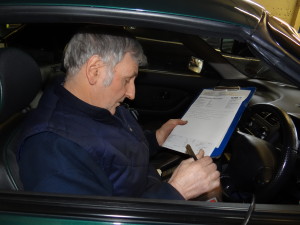

Rust on the vulnerable underside of these sportscars is another regular MOT failure point (being checked above) and, in particular, the front wishbones which, over time and exposure to moisture and salt, will rust through. Replacing the wishbones was covered in a previous article in this newsletter.

Worn bearings that allow lateral movement in the wheels (being checked below) is also a problem and again has been featured in this publication over the past 12 months.

Something that everyone can check is the condition of the tyres. MGFs and TFs have a reputation for wearing out the tyres quickly if the car is abused. Look out for uneven wear, which could be a sign of problems with the suspension – don’t just replace tyres without discovering why they are wearing unevenly. Club members are able to obtain discounts on new tyres using their 1020 membership card.

Poorly functioning brakes (being checked below) and, in particular, the hand-brake, can result in a failure – the cable for the hand-brake can become slack and may need adjusting and the connection to the brake lights is subject to wear: again covered in a previous article.

Finally, one of the most common causes of an MOT rejection is high CO2 emissions; something that can’t be easily checked without using specialist equipment. A regular cause is the failure of the Lambda sensor in the exhaust manifold.

Next Month: Replacing the Lambda senor.